Automatic Assembly Line

BS Medical manufactures more than 20 kinds of medical equipment manufacturing facilities such as Vacuum blood tube, Pen needle, Syringe, IV catheter, etc.

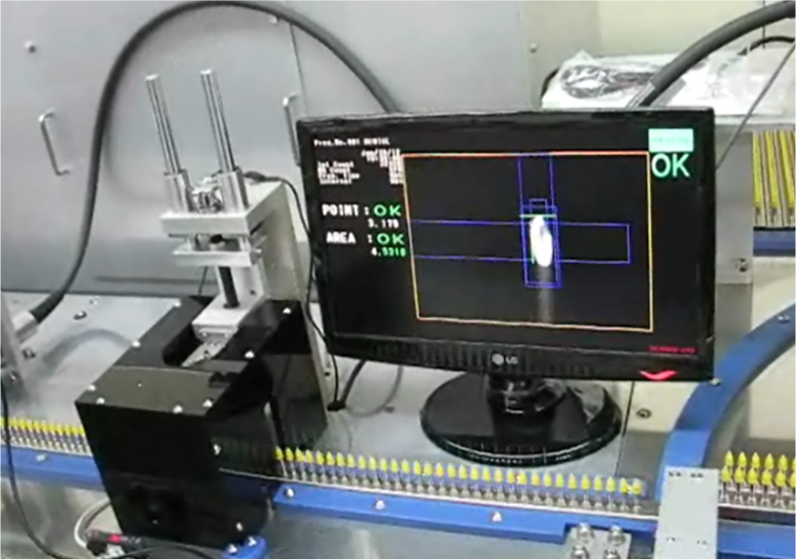

All equipment has obtained CE certification recognized for quality and technology. In particular, BS Medical’s facilities are equipped with unmanned inspection and automatic sorting system (defective product), So that realized highly productivity and maximum cost reduction by precisely inspecting and minimizing staffing.

BS Medical not only supplies automatic production line of existing products, also supplies equipment in various forms as the clients’ request.

In detail, with expertise in medical devices BS medical provides a wide range of consulting including market analysis, cost analysis, material supply and demand, production, process control, plus marketing, which needs for production and sale.

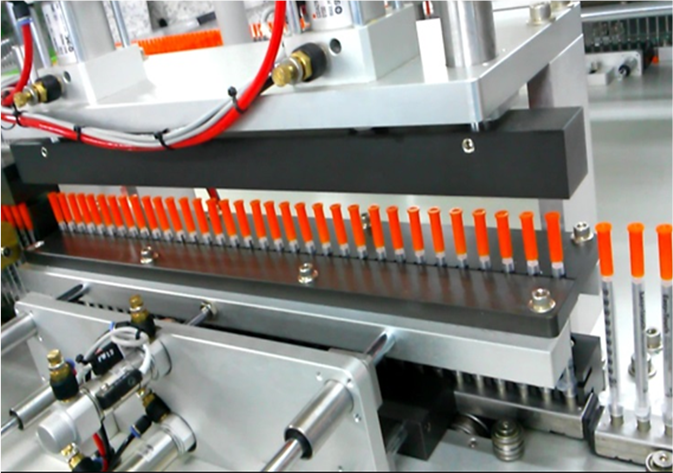

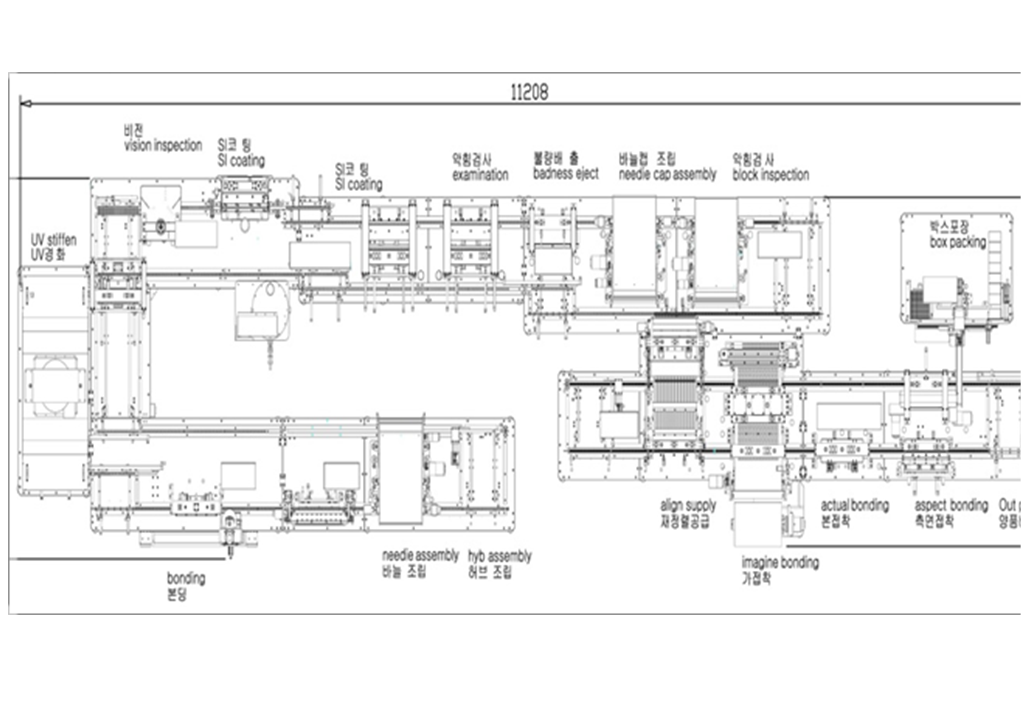

1. Insulin Syringe Assembly Line (with auto packing)

| Division |

Specification |

Remark |

| Dimension |

7900*3400*1800 |

|

| Electric Power |

AC220V,60/50Hz |

|

| Electric Power Consumption |

3.0kw |

|

| Air Consumption |

600 Liter/min |

|

| Inspection |

Vision system |

|

| Differential pressure blockage |

|

| Production Capacity |

25,000pcs/hour |

|

| No.of Worker |

2 persons (Assem1, Pack1) |

|

| Jig Type |

30pins / 2types |

|

| Other |

embedded barrel printer |

|

| UV stiffening |

|

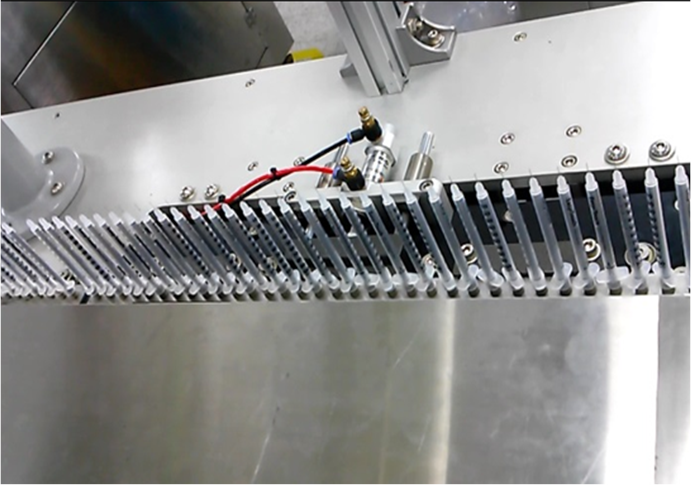

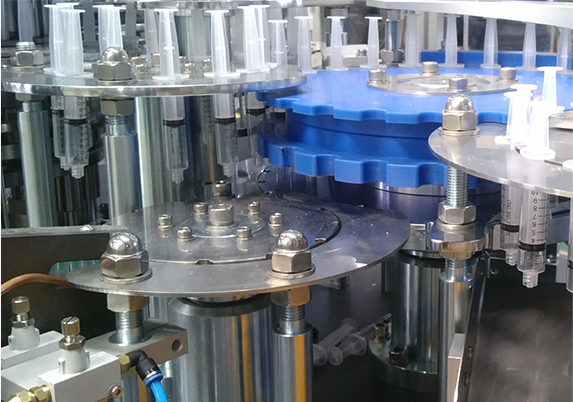

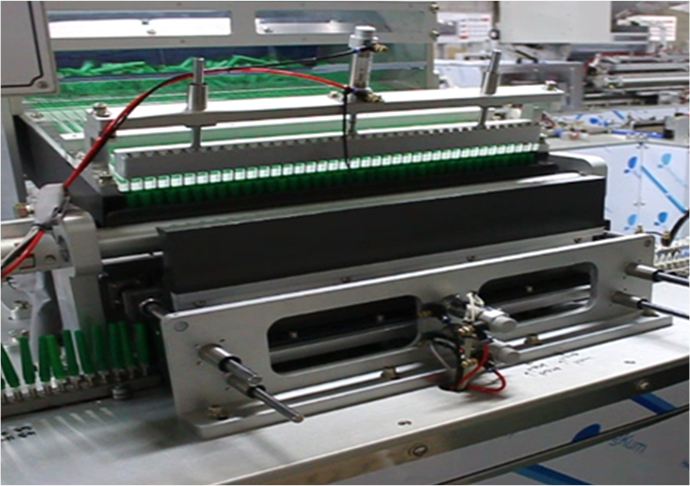

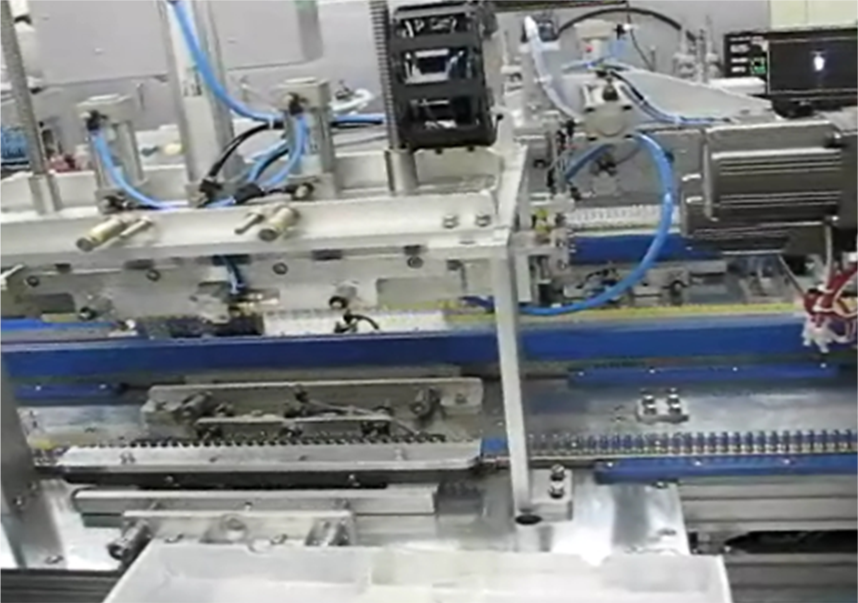

2. Conventional Syringe Assembly Line(with auto packing)

| Division |

Specification |

Remark |

| Application Process |

Printing & Packing |

|

| Dimension(L*W*H) |

3000*4000*1870 |

|

| Weight(Kg) |

2000 |

|

| Frame Material |

A6061, Profile |

|

| Electric Power |

AC220V,60/50Hz |

|

| Electric Power Consumption |

3.0kw |

|

| Air Consumption |

600 Liter/min |

|

| Production Capacity |

5,000~20,000 pcs/hour |

|

| No.of Worker |

1 persons auto supply |

|

| Jig Pin Q'ty |

50 pcs |

|

| Other |

Automatic Blister packing Machine |

|

4. Blood Collection Tube Assembly Line

| Division |

Specification |

Remark |

| Dimension (L*W*H) |

12.15*6.54*2.25 |

M |

| Weight(Kg) |

5 |

Ton |

| Electric Power |

AC 3P 220V 50/60Hz |

|

| Electric Power Consumption |

10 |

kw |

| Air pressure |

6 |

Kg/㎠ |

| Air Consumption |

800 |

L/min |

| Capacity |

10,000~12,000 |

Pcs/Hr |

| Number of Worker |

1 or 2 |

|

| Tray tansfer type |

Timing belt drive |

|

| Main Frame |

SB41,A6061,STS304 etc |

|

| Tray pin Q'ty |

40 |

20pcs*2lines |

| Control system |

PC based control |

|

| O/S |

Windows7 |

|

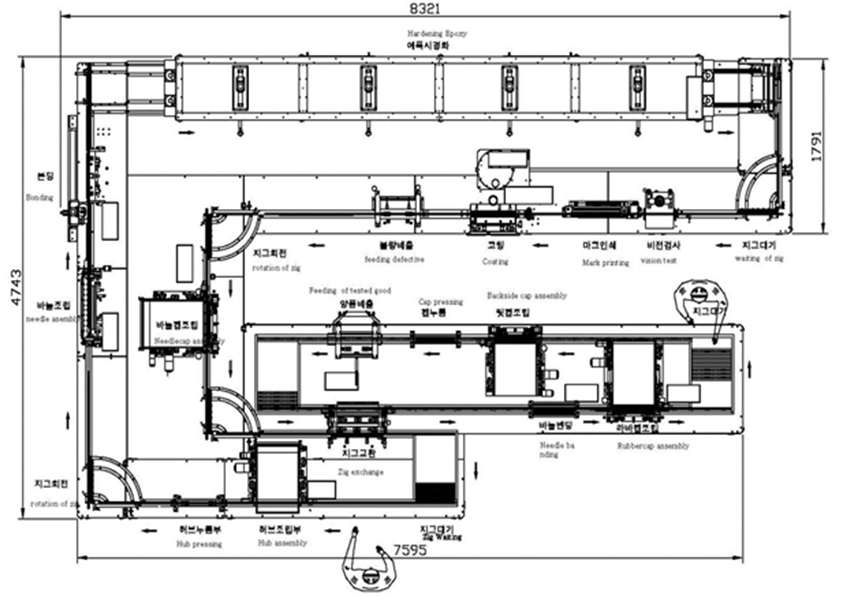

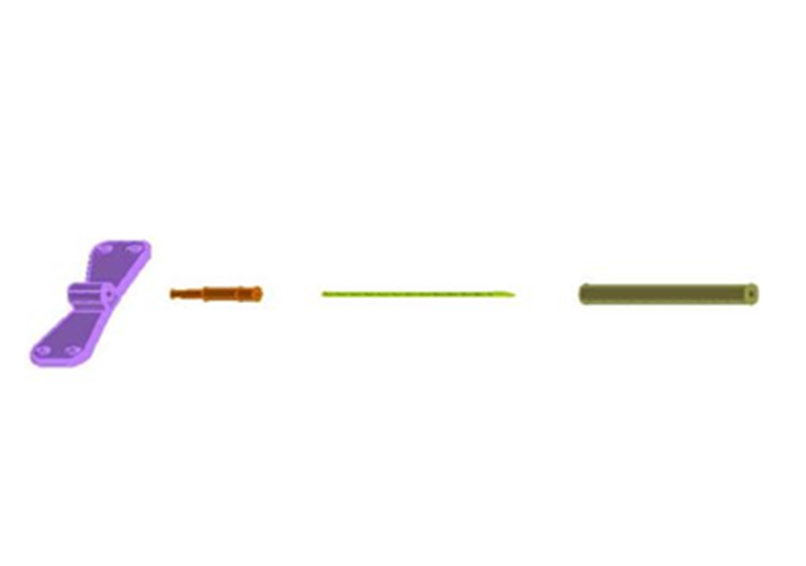

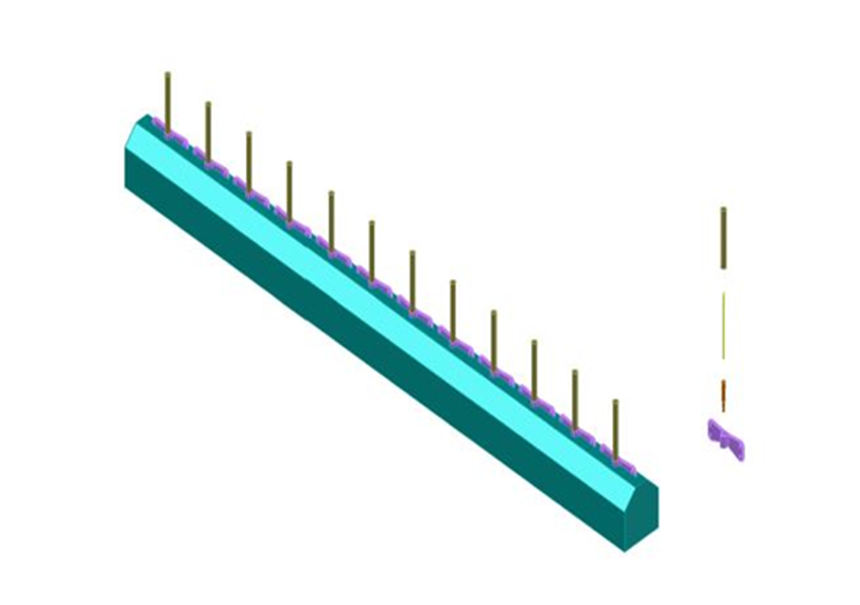

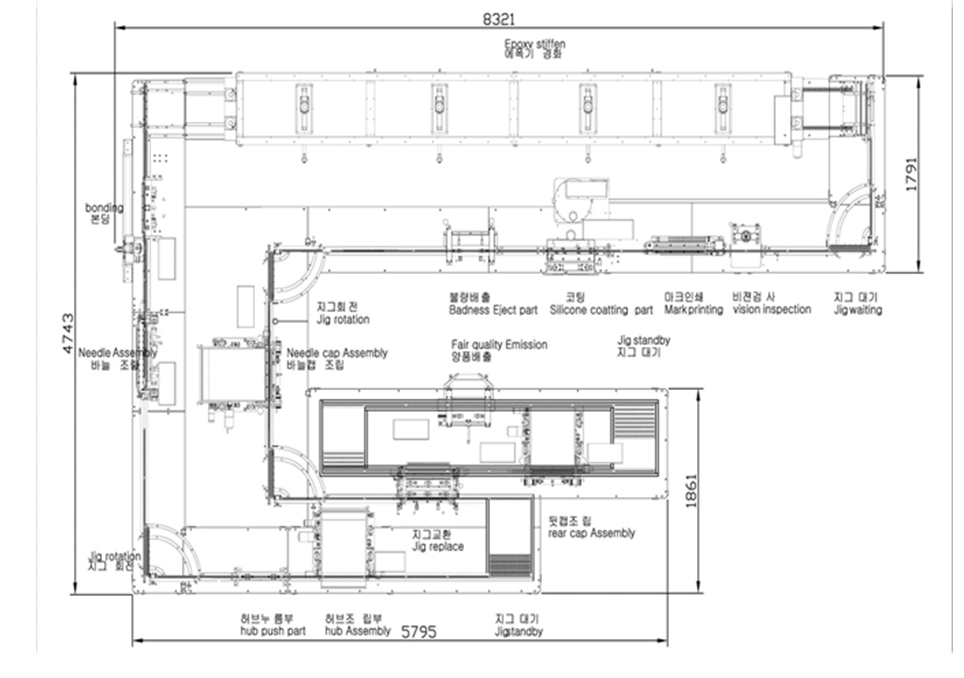

5. Blood Collection Needle Assembly Line

| Division |

Specification |

Remark |

| Dimension (L*W*H) |

8.4*4.8*1.8 |

M |

| Weight(Kg) |

3.5 |

Ton |

| Electric Power |

AC 4P 220V 50/60Hz |

|

| Electric Power Consumption |

20 |

kw |

| Air pressure |

6 |

Kg/㎠ |

| Air Consumption |

1500 |

L/min |

| Capacity |

18,000 |

Pcs/Hr |

| Number of Worker |

2 |

|

| Main Frame Material |

AL62661 Cr Hard Coating |

|

| Hub supply |

Shut type |

|

| Cannula supply |

Lift type |

|

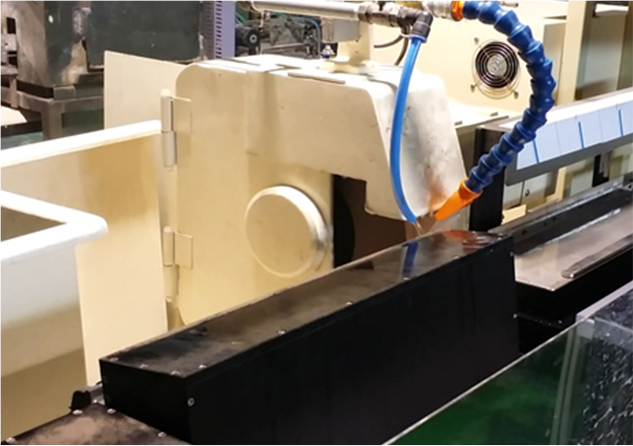

| Bonding thpe |

Wheel type(Epoxy) |

|

| Inspection system |

Tip point |

|

| Reserved cannula |

|

| Cannula Length |

|

| Tip orientation |

|

| Bonded condition |

|

| Jig pin Q'ty |

35 |

Pcs |

| Ejecting system |

Auto Defective product extracting |

|

| Control system |

P.L.C |

|

6. Scalp Vein Assembly Line

| Division |

Specification |

Remark |

| Dimension(L*W*H) |

8070*5100*1400 |

|

| Weight(Kg) |

3500 |

|

| Frame Material |

A6061 |

|

| Electric Power |

4P AC380V |

|

| Electric Power Consumption(kw) |

20 |

|

| Air Consumption |

6kg/㎠, 60 Liter/min |

|

| Jig pin |

12 pins |

|

| Inspection system |

Sensor |

|

| Inspection Point |

Needle : point/length/opposit direction |

|

| Blockage : Different pressure sensor |

|

| System controller |

PLC |

|

| Capacity |

8500 pcs/hour |

|

| Number of workers |

1 person |

|

7. Cannula Manufacturing Line

| Division |

Specification |

Remark |

| Dimension |

8,400*4,800*1,800 |

|

| Weight |

3500 kg |

|

| Jig Pin Q'ty |

50 pcs |

|

| Electric Power |

4P AC380V,60/50Hz |

|

| Electric Power Consumption |

20kw |

|

| Air Consumption |

900 Liter/min |

|

| No. of Worker |

2person auto supply |

|

| System Controller |

Sensor |

|

| Inspection system |

Full automatic Vision Camera system |

|

Inspection : location/durection/length/

opposite direction/blockage/shape |

|

| Others |

Feeding only defective

(no process after feeding location)

Remote real time mornitoring nad control |

|

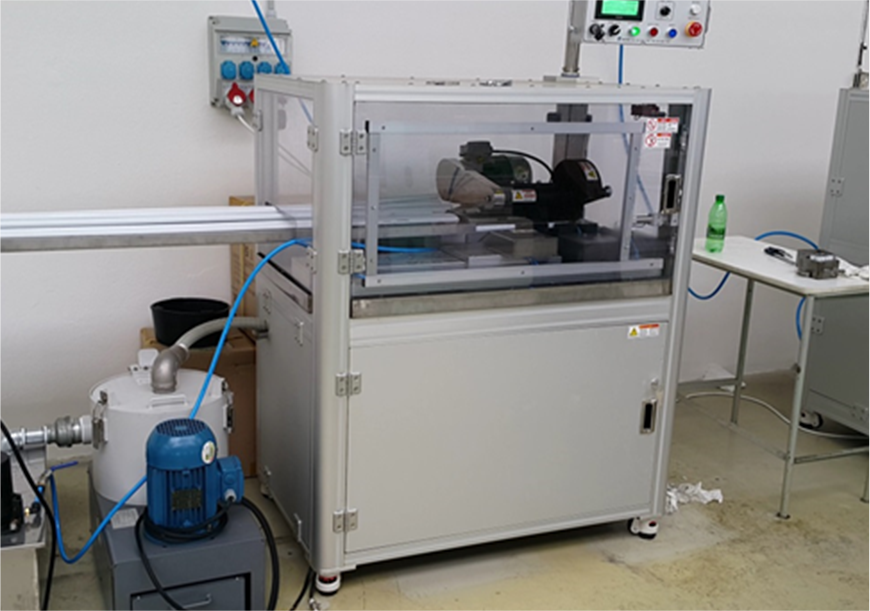

8. IV Catheter Assembly Line

| Division |

Specification |

Remark |

| Dimension |

12000*8000*1800 |

|

| Weight |

4500 kg |

|

| Jig Pin Q'ty |

36 pcs |

|

| Electric Power |

4P AC380V,60/50Hz |

|

| Electric Power Consumption |

10kw |

|

| Production |

4000 pcs/hour |

|

| No. of Worker |

4person |

|

| System Controller |

PLC |

|

| Inspection system |

Full automatic Vision Camera system |

|

Inspection item : Needle location/Direction

Length/Opposite /Blockage |

|

| Others |

Remote real time mornitoring nad control |

|

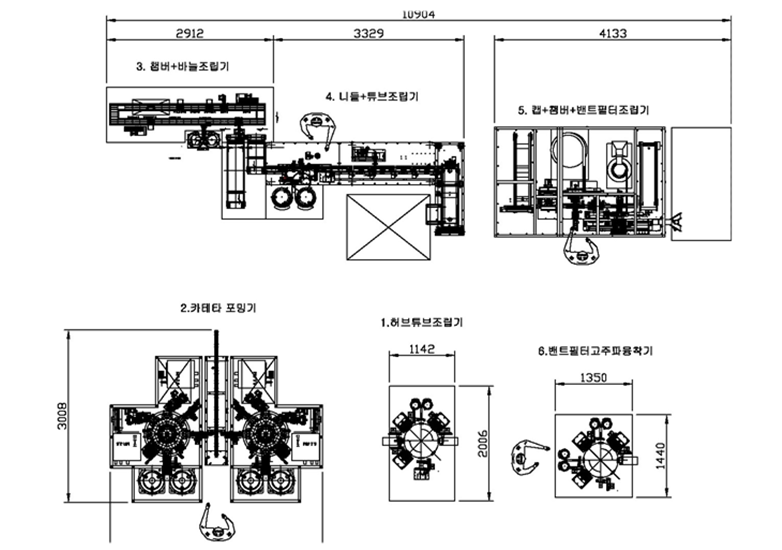

9. Pen Needle Assembly Line

| Division |

Specification |

Remark |

| Dimension |

11000*2700*1400 |

|

| Weight |

3500 kg |

|

| Jig Pin Q'ty |

25 pcs |

|

| Electric Power |

4P AC380V,60/50Hz |

|

| Electric Power Consumption |

10kw |

|

| Air Consumption |

900 Liter/min |

|

| Production Capacity |

2,000 pcs/hour |

|

| No. of Worker |

2 person auto supply |

|

| System Controller |

PLC |

|

| Inspection system |

Full automatic Vision Camera system |

|

Inspection item : Needle location/Direction/

Length/Opposite /Blockage |

|

| Others |

Remote real time mornitoring nad control |

|

10. Dental Needle Assembly Line

| Division |

Specification |

Remark |

| Dimension |

8400*4800*1800 |

|

| Weight |

3500 kg |

|

| Jig Pin Q'ty |

36 pcs |

|

| Electric Power |

4P AC380V,60/50Hz |

|

| Electric Power Consumption |

20kw |

|

| Air Consumption |

900 Liter/min |

|

| Production Capacity |

35,000 pcs/hour |

|

| No. of Worker |

2 person |

|

| System Controller |

PLC |

|

| Inspection system |

Full automatic Vision Camera system |

|

Inspection item : Needle location/Direction/

Length/Opposite /Blockage |

|

| Others |

Remote real time mornitoring nad control |

|

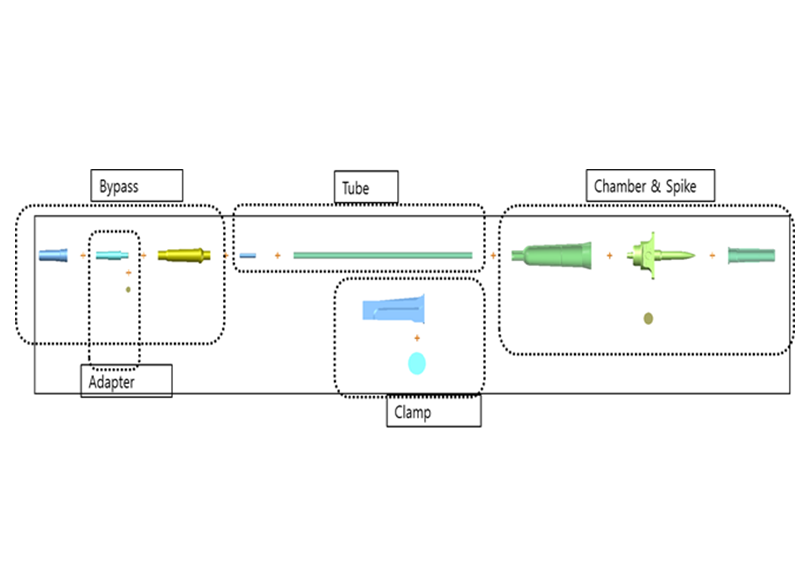

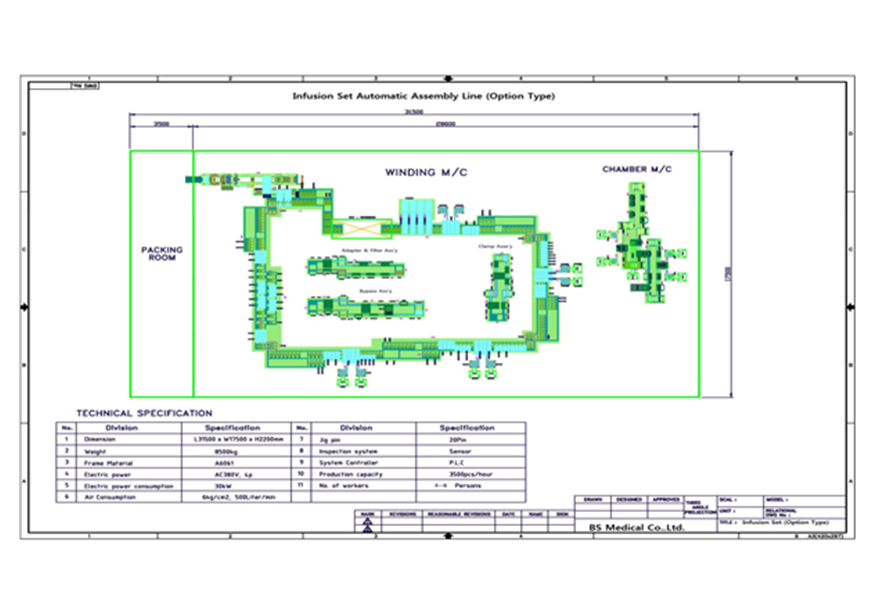

11. IV Infusion set Assembly Line

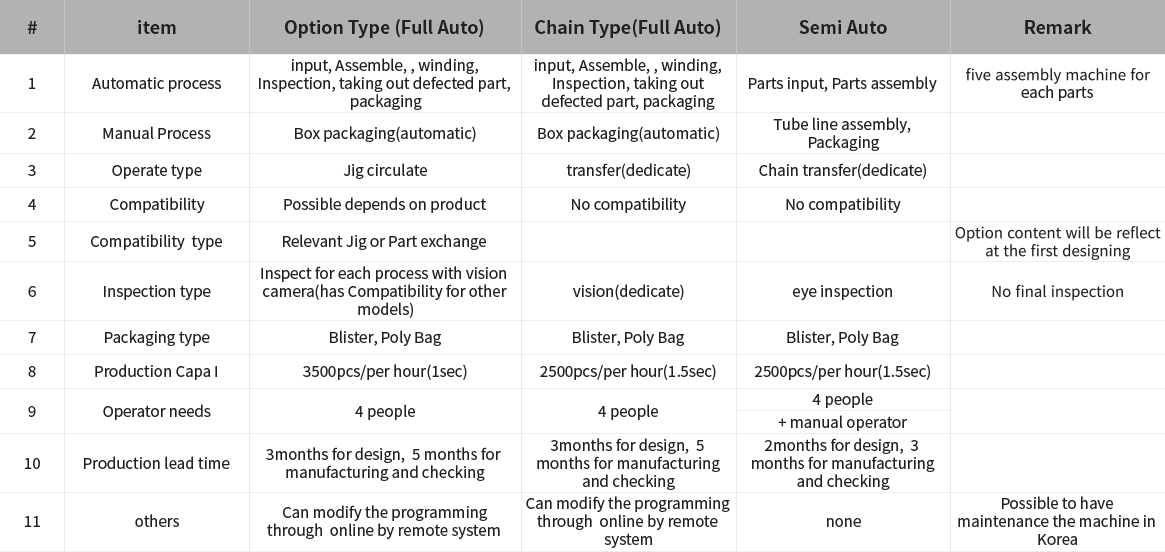

- 1) Banding is necessary in tube line for automatic packaging.

- 2) Detail estimate can be known after choosing product and specification.

- 3) Production standard as right picture.

- 4) Changing specification will need to change design as well.

- 5) Design changing causes estimate changes.

| Division |

Specification |

Remark |

| Dimension |

31500*17500*2200 |

|

| Weight |

8500 kg |

|

| Electric Power |

AC380V 4P |

|

| Air pressure |

6kg/㎠ |

|

| Air Consumption |

500 Liter/min |

|

| Material of Frame |

A6061 |

|

| Jig Pin |

20 pcs |

|

| Product capacity |

3500pcs/hour |

|

| Inspection Method |

Sensor |

|

| Programing logic controller |

Panasonic |

|

| No. of Worker |

4 person |

|

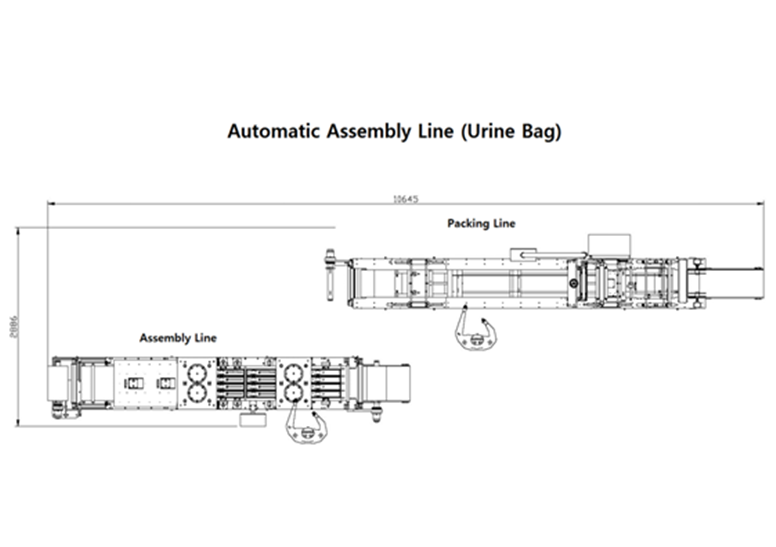

12. Urine Bag Assembly Line

| Division |

Specification |

Remark |

| Dimension |

11000*3000*1800 |

|

| Weight |

3500 kg |

|

| Electric Power |

AC380V 4P |

|

| Consumption of electric Power |

25kw |

|

| Consumption Air |

100 Liter/min |

|

| Capacity(Automatic) |

450pcs/Hr |

|

| Capacity(Semi-auto) |

300pcs/Hr |

|

| Material of Frame |

A6061 |

|

| Product capacity |

Sensor |

|

| Programing logic controller |

Panasonic |

|

| No. of Worker |

1~2 person |

|

13. Injection Machine & Mold

Electric Injection Molding Machine

Electric Injection Molding Machine

These exceptional machines combine the benefits of servo electric technology, an injection speed / pressure control algorithm,

conformance to safety standards, a 5-point toggle clamping system designed by FEA analysis, and a high speed

injection molding mechanism.

Hybrid system

Hybrid system

Closed-loop system speed pressure preset by controller is transferred to the pump control valve and is compared

to actual valve from sensor for corrective feedback.

Electric Injection Molding Machine

Electric Injection Molding Machine Hybrid system

Hybrid system